As recently as 2015, The National Institute of Health and Care Excellence, abbreviated as NICE, in the United States has sanctioned an ultrasound system of comparatively low intensity, that goes by the name of Exogen. This technology would be used by the National Health Services, on severe cases of bone fracture. The international market is sprawled with start ups and established names, who are pitching their bid to make healing a much more efficient, beautiful, and patient friendly experience. Read as to what are the benefits of 3D print ultrasound casts in case of Bone fracture.

1Application of 3D Printing in Medical Science

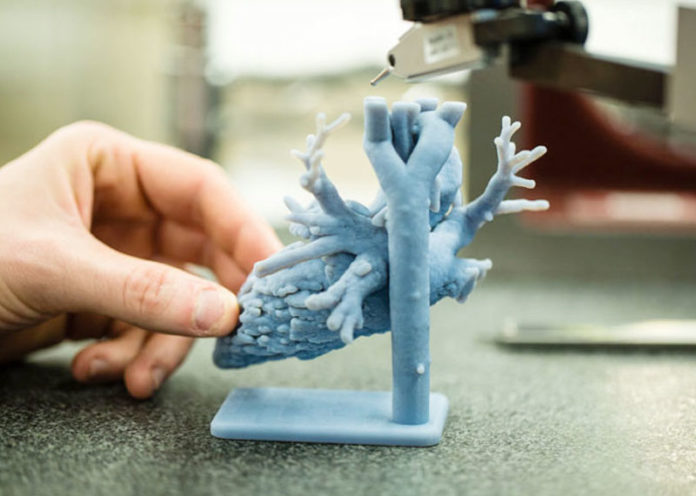

The growth of the 3D printing technology industry has been a steady one. With the capacity to print a razor blade, to intricate parts of ammunition, automobiles, and air crafts. All done, by the mere turning of a needle. Medical science could not said to be left behind in the field. 3D printed hearts, livers and other organs, are still under study, due to the rather infancy in the technology. Yet the 3D printing of common to complex medical devices has been a common practice now for some years. Companies have been known to create umbilical chord clamps on the spot with the use of 3D printers.

Yet when it has come to the grotesque, allergy promoting, malodorous, sticky to touch, plaster cast, a lot has been left ignored for far too long. The common practice has undergone little evolution for as long back as one could remember. The use of these 3D printed ultrasound casts provide a number of benefits when compared to the traditional system that has been thus followed so far.

23D Printing of Casts

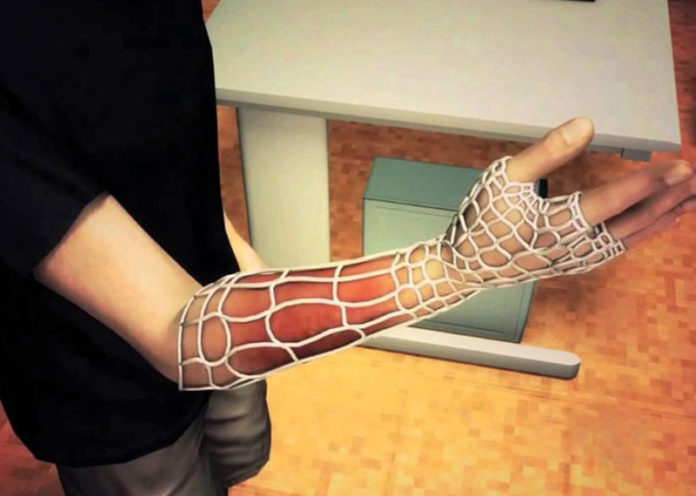

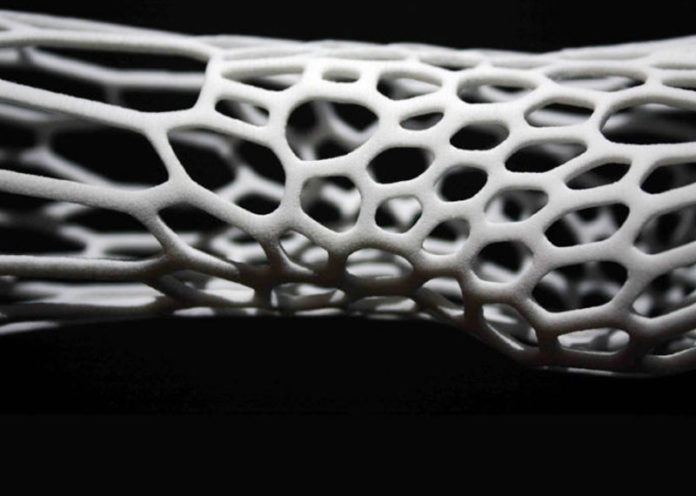

3D printing of casts, used in industrial applications is not something uncommon. Yet its use in treatment of bone fracture has been limited until very recently. Research has now been undertaken on designs, based on geometric patterns to develop different varieties of casts that would serve exclusive purposes. Certain variations work literally as a brace, on the bone. The casts in these cases are exclusively printed for each individual withe the help of 3D scanning. The specific brace variety comes with a host of added features. It is water resistant, hence washable. It is a self respiring system and hence prevents the development of rashes and infections on the skin. It looks sleek and inconspicuous and could be made denser around the areas which are more severely affected, where the fracture needs added reinforcements.

Other variations include designs which wrap around the thumb for an additional grip. Most of these designs implement a technology which is based on the holding onto of the cast, close to the skin, rather than forming a fit around the bone. A certain geometric algorithmic logic has to be followed, with respect to the location of the injury, in either cases by the research and development teams of the competing firms.

This needs to be done, in order to come up with standards that are accepted and appreciated world wide. The vision of the companies may not vary as in principle, as it may vary in technical literature, which is based on the difference in geometric patterns, and mode of approach to repair. Depending on the acceptance of the technology by the medical fraternity, it becomes mainstream or unconventional in the market.

Also Read: Why Healthcare is a Business and not a Fundamental Right

3The Different Designs of 3D Printed Casts

The fundamental aspect which brings about the difference in designs are the inspirations. While some firms may look at the process of healing the fracture with spongy bone geometry. This philosophy, is used in the case of the skin fitting casts, compared to those which concentrate their effect on the specific region of the bone which has undergone fracture. The conventional philosophy aims at healing the fracture by spreading the efforts over a an area through the structural integrity of the supporting cast itself.

The advocates of this technique believe that their mode of therapy brings about more efficient reinforcement of the fractured region. The same circles claim that their competing technology approach the process of reassembling of the bones in a snappy and inefficient manner. Which may not be very healthy for the effectiveness of the cure in terms of longevity.

The technology based on the conventional philosophy, implements the use of two pieces, aided by a secondary locking mechanism, to ensure that the cast holds onto the region which it is meant to. Where as the snapping technology, comes with a one time fit.

4The Current State of Affairs

The latest technology Exogen, which has been approved for the use of NHS by NICE, uses ultrasound probes which are fixed into the cast. Medical studies have shown that administration of ultrasound waves promote the healing of bone. The process is brought about by stimulating the production of the growth hormones and proteins, which enhances the removal of old bone tissues and production of new ones. The ultrasound waves although, may have some adverse effects on the skin, bringing about superficial swelling. In the long run, this technology is been looked upon as a replacement for surgeries, which needs to be undergone in cases of severe episodes of fracture.

By Abhro